Factory supplied Printed Circuit Board Assembly - Custom-made PCB enclosure Fully Assembled Non-Contact Thermometer Infrared Forehead Thermometer PCB,PCBA Assembly For Infrared Thermometer – PhiliFast

Factory supplied Printed Circuit Board Assembly - Custom-made PCB enclosure Fully Assembled Non-Contact Thermometer Infrared Forehead Thermometer PCB,PCBA Assembly For Infrared Thermometer – PhiliFast Detail:

PRODUCT SPECIFICATION:

Turnkey Sevices: 1. PCB fabrication 2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing

Main Product:

Our Advantage:

1, Programming and Functional test 2, IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test. 3, Professional service. ISO SMT and through hole assembly, over 10 years experience. 4, Certification: 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001 5, Warranty period for PCBA: 2 years.

PCBA PROCESSING CAPABILITY:

PCB PROCESSING CAPABILITY:

Fast Delivery: PCB In 12Hours PCBA In 3Days Main Products Application: *Medical Products * Automotive Products * Industrial Products * Communication Products(AVL/GPS/GSM Devices) * Consumer Electronics. PCB Assembly Procedures: * Program Management PCB Files → DCC → Program Organizing → Optimization → Checking * SMT Management PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping * PCBA Management THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment PHILIFAST provides you the best PCB manufacture and assembly experience

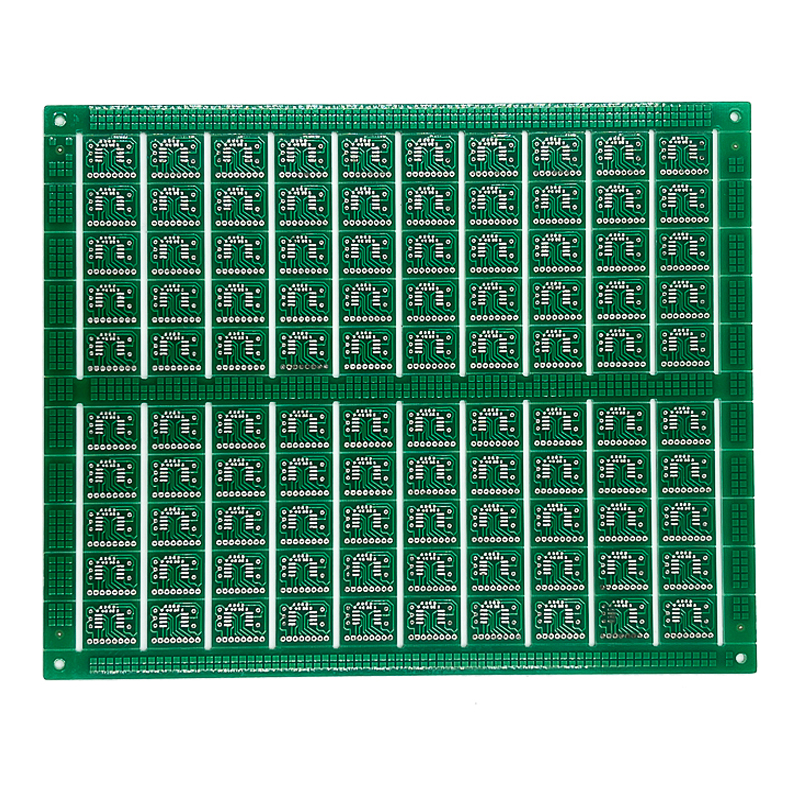

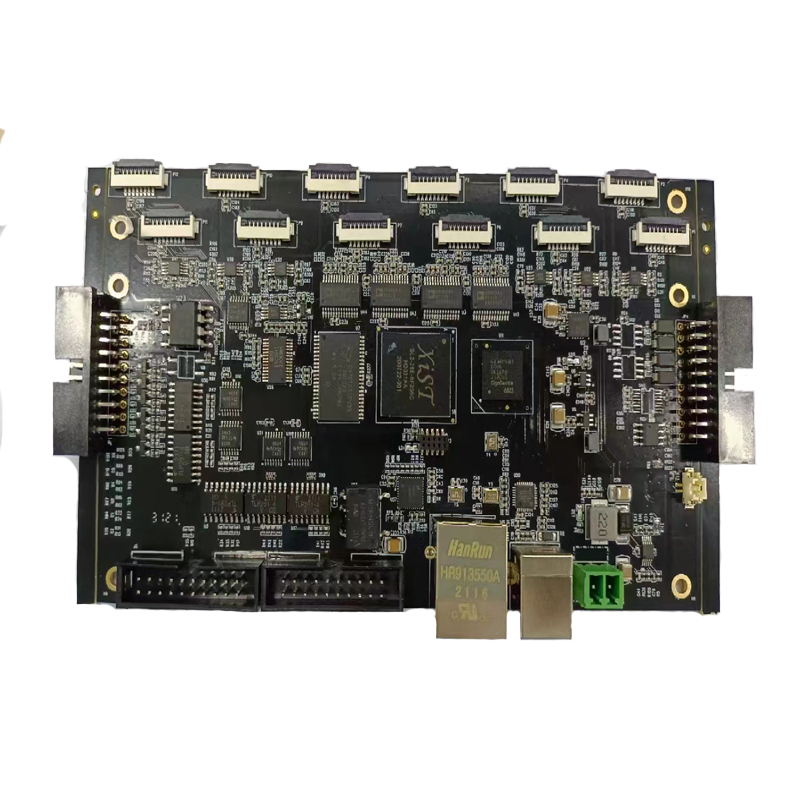

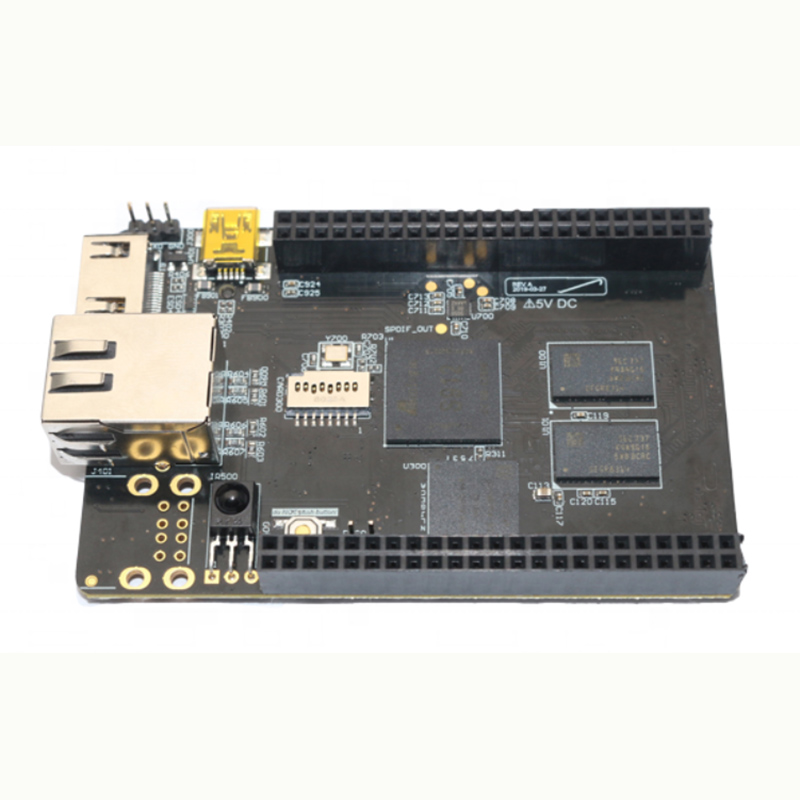

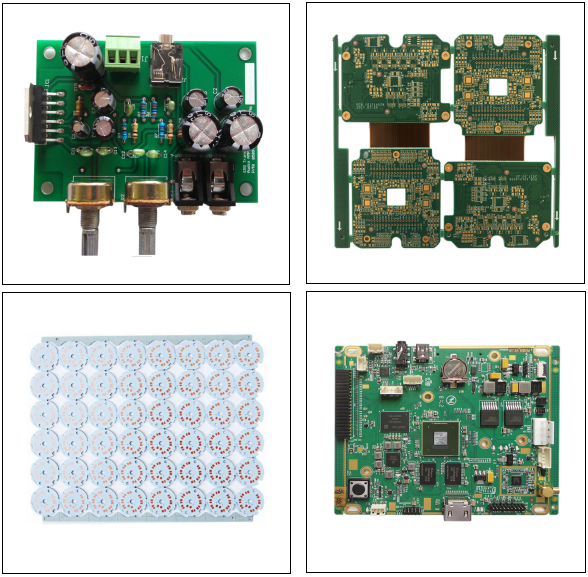

Product detail pictures:

Related Product Guide:

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Factory supplied Printed Circuit Board Assembly - Custom-made PCB enclosure Fully Assembled Non-Contact Thermometer Infrared Forehead Thermometer PCB,PCBA Assembly For Infrared Thermometer – PhiliFast, The product will supply to all over the world, such as: Philippines, Swiss, azerbaijan, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.