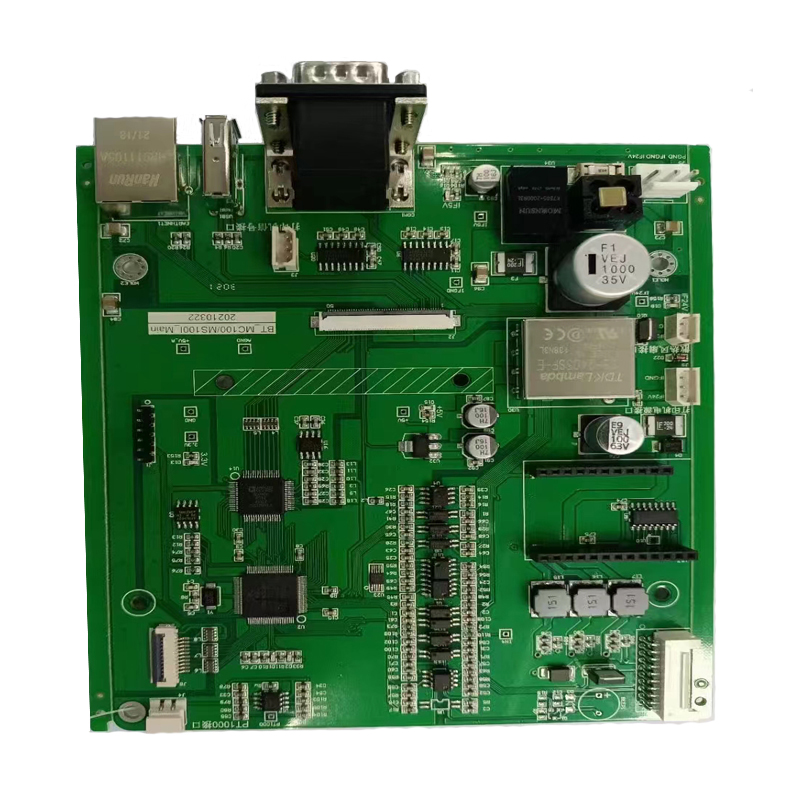

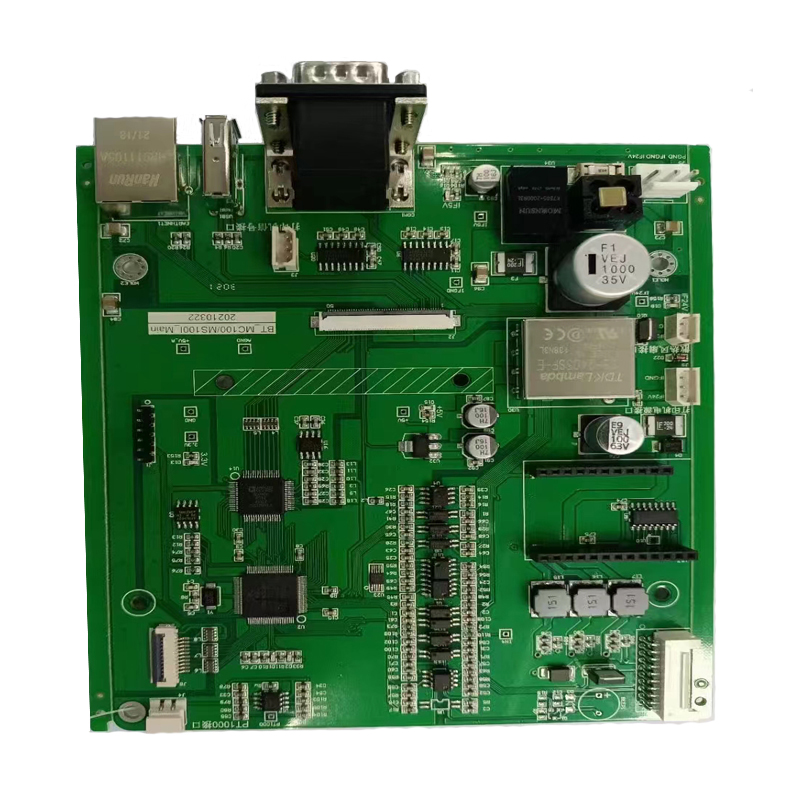

China New Product Smt In Manufacturing - Turnkey Circuit Board Assembly PCB&PCBA OEM Electronics Manufacturer Double-sided Communication PCB Manufacturer for Networking Devices – PhiliFast

China New Product Smt In Manufacturing - Turnkey Circuit Board Assembly PCB&PCBA OEM Electronics Manufacturer Double-sided Communication PCB Manufacturer for Networking Devices – PhiliFast Detail:

PRODUCT SPECIFICATION:

Turnkey Sevices:

1. PCB fabrication

2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing

Main Product:

Our Advantage:

1, Programming and Functional test

2, IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test.

3, Professional service. ISO SMT and through hole assembly, over 10 years experience.

4, Certification: 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001

5, Warranty period for PCBA: 2 years.

PCBA PROCESSING CAPABILITY:

PCB PROCESSING CAPABILITY:

Fast Delivery:

PCB In 12Hours

PCBA In 3Days

Main Products Application:

*Medical Products

* Automotive Products

* Industrial Products

* Communication Products(AVL/GPS/GSM Devices)

* Consumer Electronics.

PCB Assembly Procedures:

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

PHILIFAST provides you the best PCB manufacture and assembly experience

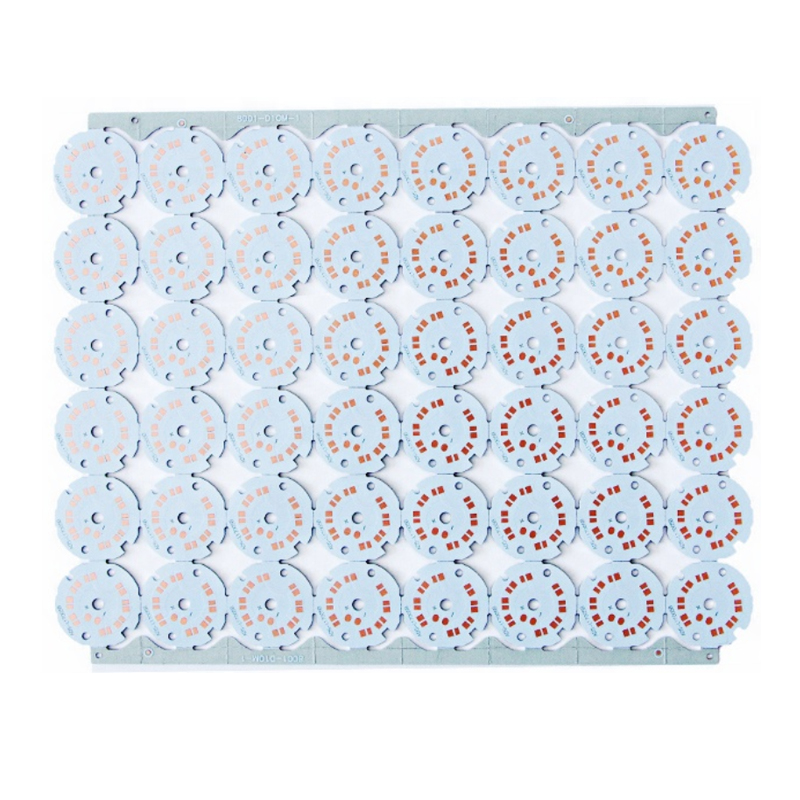

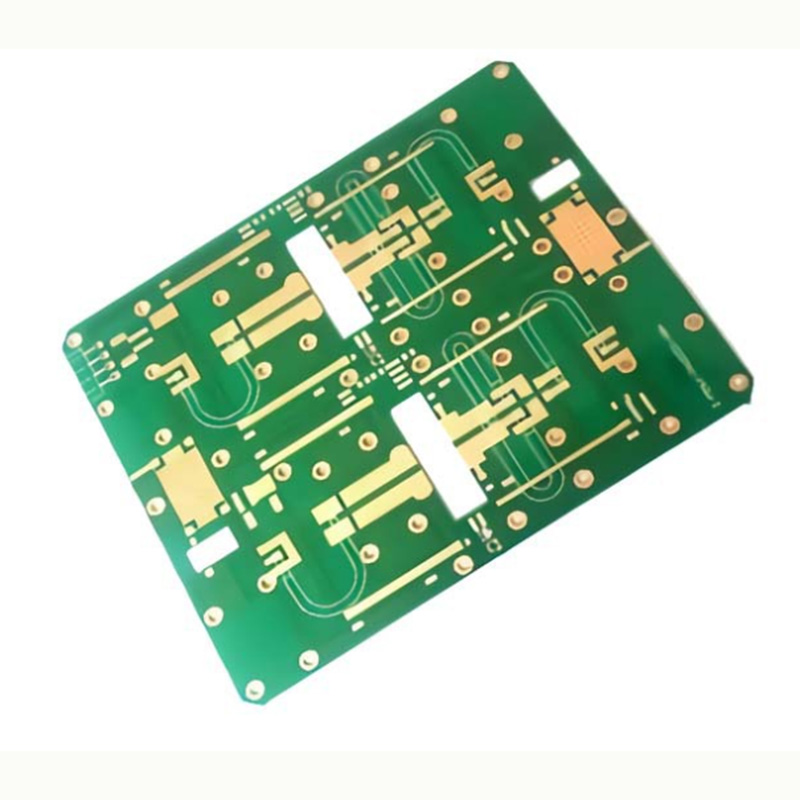

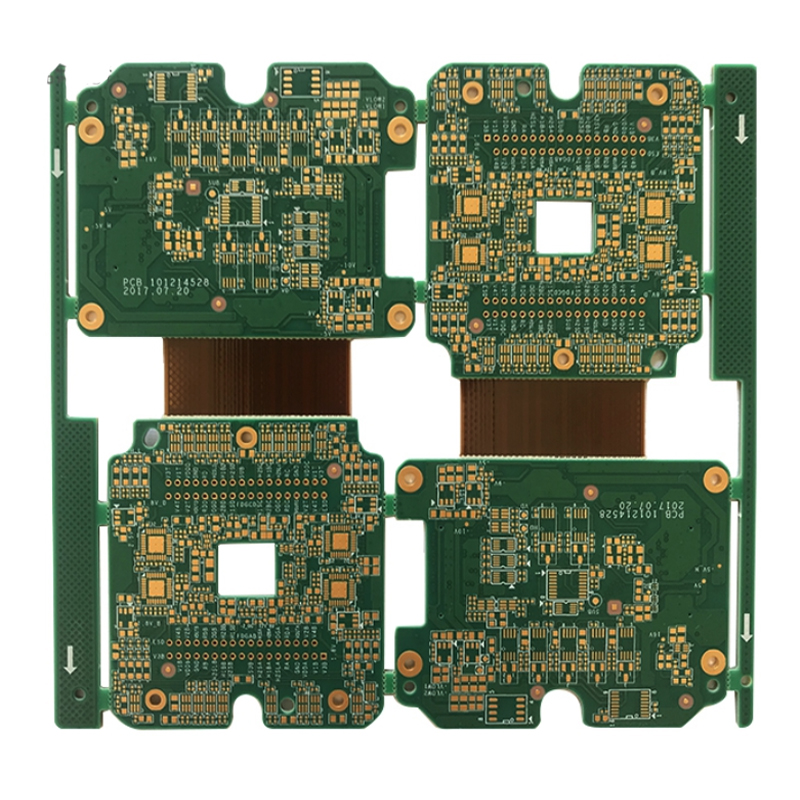

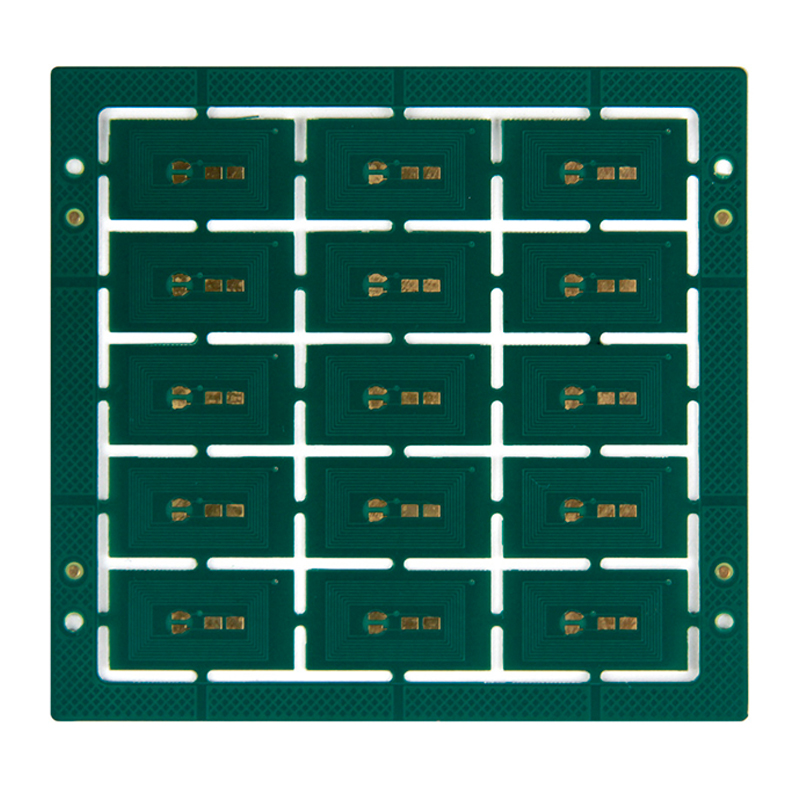

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for China New Product Smt In Manufacturing - Turnkey Circuit Board Assembly PCB&PCBA OEM Electronics Manufacturer Double-sided Communication PCB Manufacturer for Networking Devices – PhiliFast, The product will supply to all over the world, such as: Paris, Bolivia, Canada, The president and all the company members would like to provide professional products and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.