Big discounting Pcb Soldering Service - Turnkey PCB Assembly Electronic Printed Pcb Circuit Board Manufacturer In China PCBA boards – PhiliFast

Big discounting Pcb Soldering Service - Turnkey PCB Assembly Electronic Printed Pcb Circuit Board Manufacturer In China PCBA boards – PhiliFast Detail:

PRODUCT SPECIFICATION:

Turnkey Sevices:

1. PCB fabrication

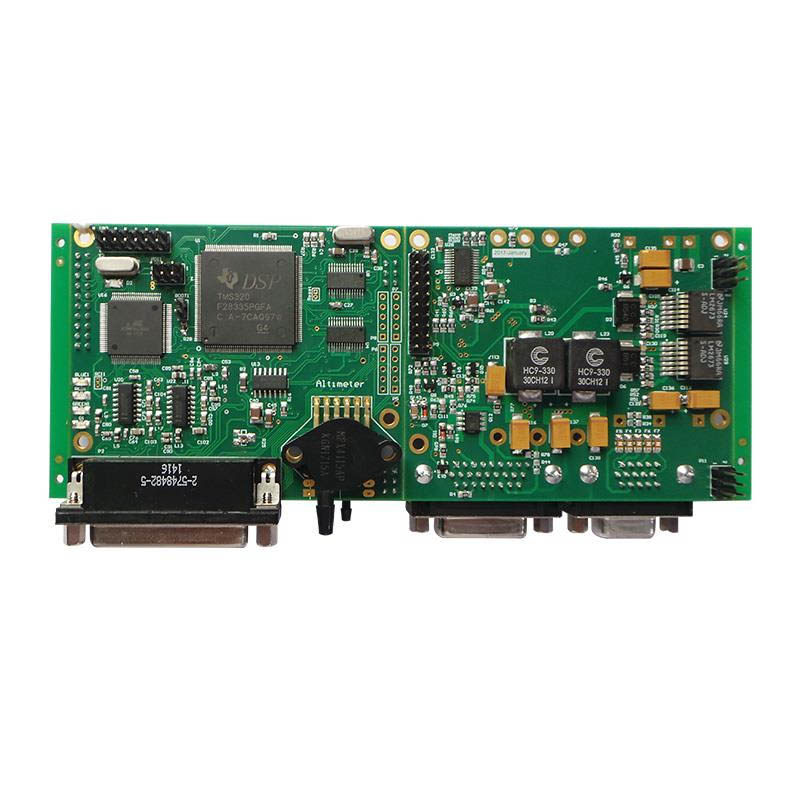

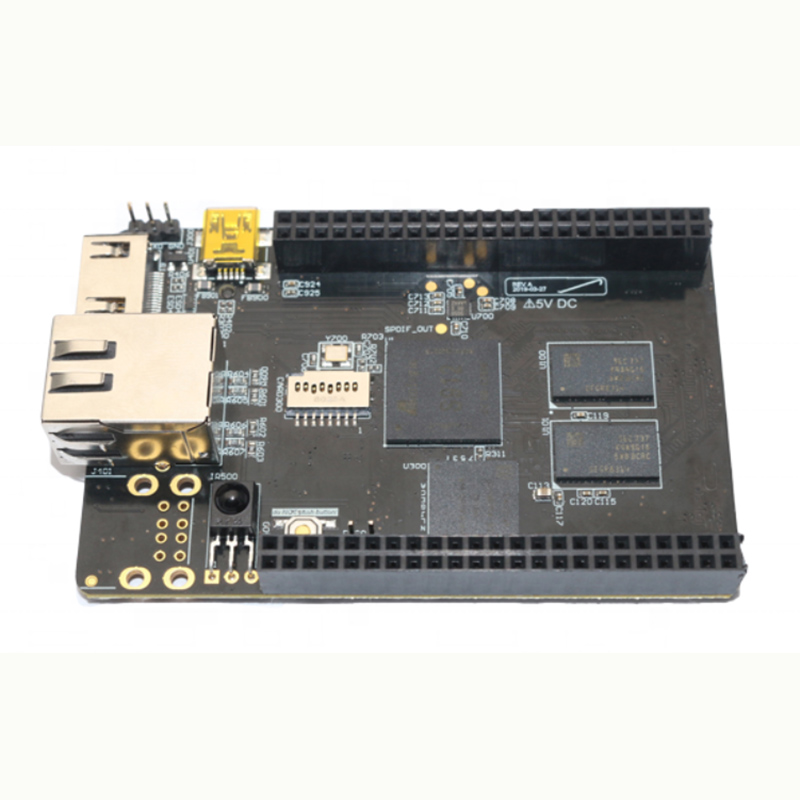

2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing

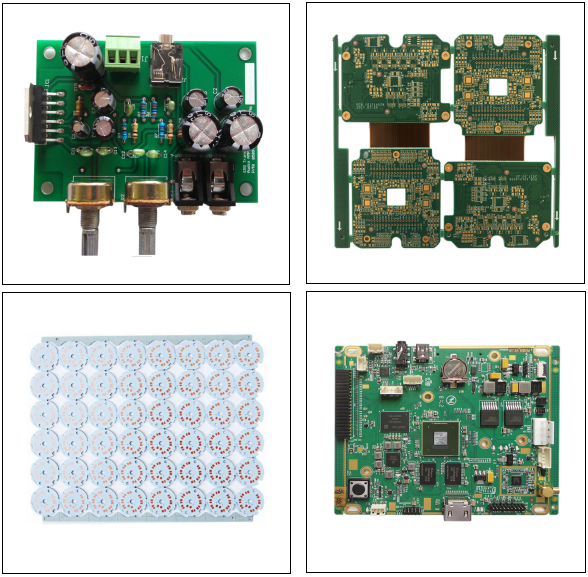

Main Product:

Our Advantage:

1, Programming and Functional test

2, IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test.

3, Professional service. ISO SMT and through hole assembly, over 10 years experience.

4, Certification: 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001

5, Warranty period for PCBA: 2 years.

PCBA PROCESSING CAPABILITY:

PCB PROCESSING CAPABILITY:

Fast Delivery:

PCB In 12Hours

PCBA In 3Days

Main Products Application:

*Medical Products

* Automotive Products

* Industrial Products

* Communication Products(AVL/GPS/GSM Devices)

* Consumer Electronics.

PCB Assembly Procedures:

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

PHILIFAST provides you the best PCB manufacture and assembly experience

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Big discounting Pcb Soldering Service - Turnkey PCB Assembly Electronic Printed Pcb Circuit Board Manufacturer In China PCBA boards – PhiliFast, The product will supply to all over the world, such as: Argentina, Wellington, Liberia, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.