Solder mast is a very important part of PCB printed circuit boards, There’s no doubts that Solder mask will help to assembly, however what else does solder mask contribute to? We’ll have to know more about solder mask itself.

What’s the solder mask?

Solder mask or solder stop mask or solder resist is a thin lacquer-like layer of polymer that is usually applied to the copper traces of a printed circuit board(PCB) for protection against oxidation and to prevent solder bridges from forming between closely spaced solder pads.

A solder bridge is an unintended electrical connection between two conductors by means of a small blob of solder.

PCBs use solder masks to prevent this from happening.

Solder mask is not always used for hand soldered assemblies, but is essential for mass-produced boards that are soldered automatically using reflow or solder bath techniques.

Once applied, openings must be made in the solder mask wherever components are soldered, which is accomplished using photolithography.

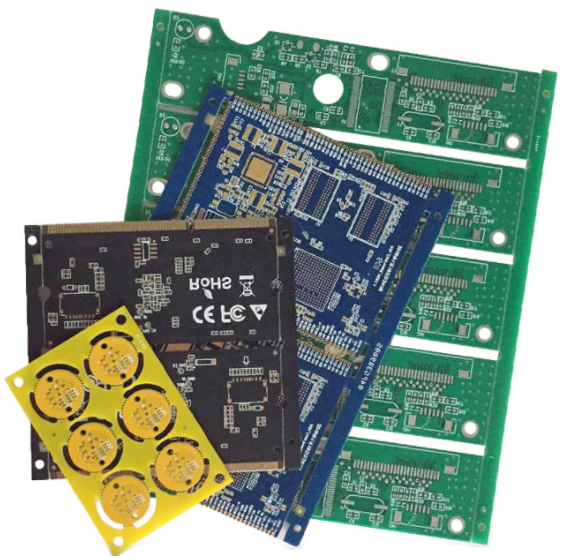

Solder mask is traditionally green but is now available in many colors.

The process of solder mask

The solder mask process includes a number of steps.

After a pre-cleaning step, in which the printed circuit boards are degreased and the copper surface is either mechanically or chemically rough end, the solder mask is applied.

There are several applications like curtain coating, screen-printing or spray coating available.

After the PCBs have been coated with solder mask, the solvent needs to be flashed-off in a tack-drying step.

The next step in the sequence is exposure. In order to structure the solder mask, artwork is used.The boards are exposed with a typical 360 nm light source.

The exposed areas will polymerize while the covered areas will remain monomer.

In the developing process the exposed areas are resistant, and the unexposed (monomer) areas will be washed out.

The final curing is done in a batch or tunnel oven. After the final curing, an additional UV cure may be needed for increasing the mechanical and chemical properties of the solder mask.

The main function of solder mask:

So what is the function of a Solder Mask?

Pick two among the list:

1. Protection from oxidation.

2. Protection from heat.

3. Protection from accidental solder bridging.

4. Protection from electrostatic discharge.

5. Protection from hyper discharge of current.

6. Protection from dust.

Except the main functions above, there are also some other application. If there’s still more questions about solder mask, Please consult experts in PHILIFAST.

Post time: Jun-22-2021